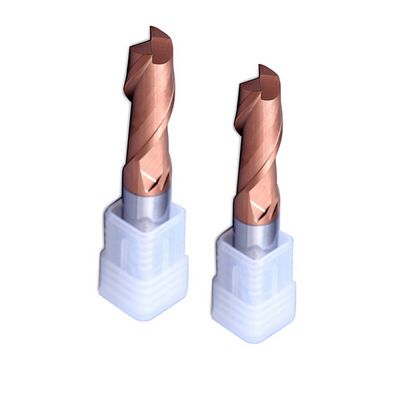

EMB09 4 Flute Corner Radius End Mill

Product Specifications

| Coating | AITiN | HRC | HRC50/65 |

| Helix Angle | 45° | Shank | Cylindrical H6 |

| Material | IMC™ UMG Carbide Rod | Tolerance on Cutting Diameter | 0-0.030 |

HRC65 Carbide End Mills, 4 Flutes, Corner Radius (UNT-EMB09)

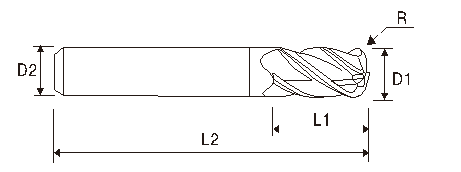

| UNT EDP # Click to Order | Corner Radius R |

Mill Dia. D1 |

Shank Dia. D2 |

Flute Length L1 |

O.A.L. L2 |

Flutes |

| EMB090101 | R0.1 | 1.0 | 4 | 3 | 50 | 4 |

| EMB090102 | R0.2 | 1.0 | 4 | 3 | 50 | 4 |

| EMB090201 | R0.1 | 2.0 | 4 | 6 | 50 | 4 |

| EMB090202 | R0.2 | 2.0 | 4 | 6 | 50 | 4 |

| EMB090203 | R0.3 | 2.0 | 4 | 6 | 50 | 4 |

| EMB090302 | R0.2 | 3.0 | 4 | 8 | 50 | 4 |

| EMB090303 | R0.3 | 3.0 | 4 | 8 | 50 | 4 |

| EMB090305 | R0.5 | 3.0 | 4 | 8 | 50 | 4 |

| EMB090310 | R1.0 | 3.0 | 4 | 8 | 50 | 4 |

| EMB090402 | R0.2 | 4.0 | 4 | 11 | 50 | 4 |

| EMB090403 | R0.3 | 4.0 | 4 | 11 | 50 | 4 |

| EMB090405 | R0.5 | 4.0 | 4 | 11 | 50 | 4 |

| EMB090410 | R1.0 | 4.0 | 4 | 11 | 50 | 4 |

| EMB090505 | R0.5 | 5.0 | 6 | 13 | 50 | 4 |

| EMB090510 | R1.0 | 5.0 | 6 | 13 | 50 | 4 |

| EMB090602 | R0.2 | 6.0 | 6 | 16 | 50 | 4 |

| EMB090603 | R0.3 | 6.0 | 6 | 16 | 50 | 4 |

| EMB090605 | R0.5 | 6.0 | 6 | 16 | 50 | 4 |

| EMB090610 | R1.0 | 6.0 | 6 | 16 | 50 | 4 |

| EMB090615 | R1.5 | 6.0 | 6 | 16 | 50 | 4 |

| EMB090620 | R2.0 | 6.0 | 6 | 16 | 50 | 4 |

| EMB090802 | R0.2 | 8.0 | 8 | 20 | 60 | 4 |

| EMB090803 | R0.3 | 8.0 | 8 | 20 | 60 | 4 |

| EMB090805 | R0.5 | 8.0 | 8 | 20 | 60 | 4 |

| EMB090810 | R1.0 | 8.0 | 8 | 20 | 60 | 4 |

| EMB090815 | R1.5 | 8.0 | 8 | 20 | 60 | 4 |

| EMB090820 | R2.0 | 8.0 | 8 | 20 | 60 | 4 |

| EMB091005 | R0.5 | 10.0 | 10 | 25 | 75 | 4 |

| EMB091010 | R1.0 | 10.0 | 10 | 25 | 75 | 4 |

| EMB091015 | R1.5 | 10.0 | 10 | 25 | 75 | 4 |

| EMB091020 | R2.0 | 10.0 | 10 | 25 | 75 | 4 |

| EMB091030 | R3.0 | 10.0 | 10 | 30 | 75 | 4 |

| EMB091205 | R0.5 | 12.0 | 12 | 30 | 75 | 4 |

| EMB091210 | R1.0 | 12.0 | 12 | 30 | 75 | 4 |

| EMB091215 | R1.5 | 12.0 | 12 | 30 | 75 | 4 |

| EMB091220 | R2.0 | 12.0 | 12 | 30 | 75 | 4 |

| EMB091230 | 12.0 | 12.0 | 12 | 30 | 75 | 4 |

• End mills with non-standard sizes or specifications not listed above can be customized according to customer needs.